Adding To The Bucket Of Experience.

Well Hello There Fellow Technicians And Hivers!

Another Toyota.

Here I am with another one of these!

Shees I sound like I do a thousand of these a week where as I really only do two a year. Well so far we've done two this year and last year only one. The Toyota's don't break as often!

Built more for reliability but when they do break you will pay quite a penny more than with Fords! Laughs so it all balances out, so to speak!

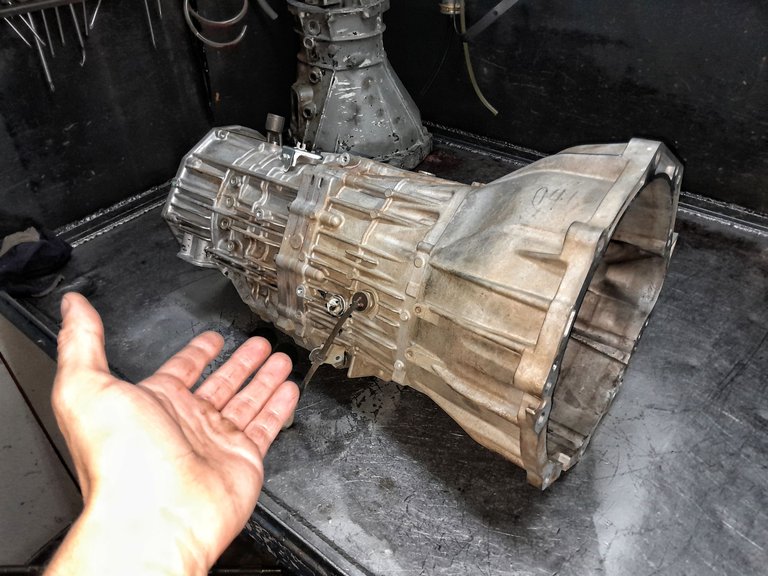

Not As Big Now Hey!

Remove a couple of stuff and it ain't as big as it use to be right!

I only removed the bell-housing so far and it looks like half the size of what it was, trust me... more than often I wonder how the hell some stuff drive with such small gears and stuff!

Okay this transmission has some thick gears in it but looking at the size and the size of the pickup it still somewhat baffles me!

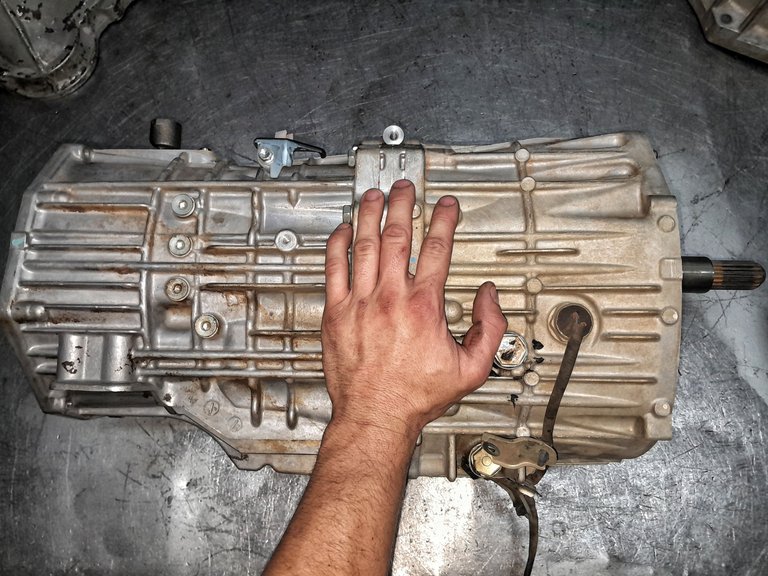

The Selector System.

So with the previous one that I tore down I unbolted a great deal more than what was needed.

I regretted that quite a bit when I had to assemble it, so this time I learnt a lesson hey! That is also the only way in life to learn lessons by experiencing the after math of the mistake.

Otherwise you won't be learning anything, especially when people fix your mistakes for you!

No Reason Here.

There is no reason to pull all of it apart, there really isn't. That's okay that I did though, we learned something with the struggle and you only gain from struggle.

Nothing that's easy in life is really worth it.

They can all be cleaned and inspected for wear without pulling that piece apart.

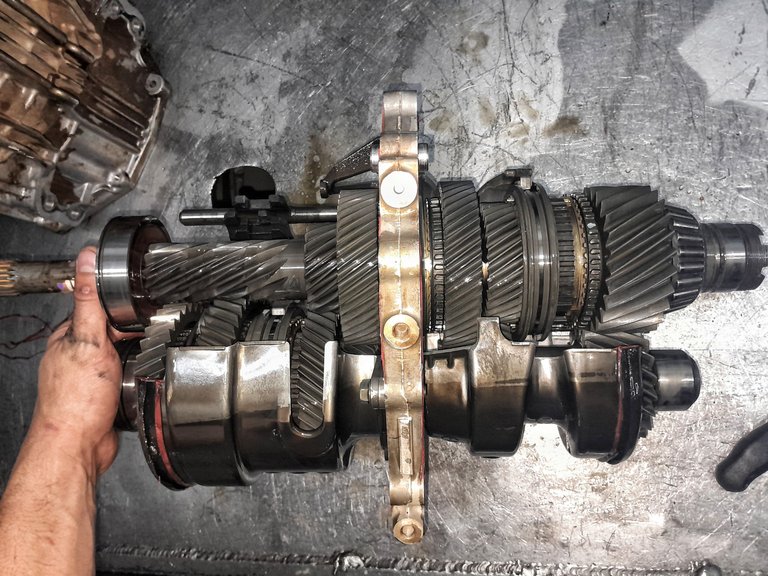

The Beauty Of It.

I'm probably just weird but I find beauty in that. Laughs I really do!

I even shared this on social now because I am awkward like that! Lels!

There wont be much to do on this one though, only a couple of synchro's and seals. Perhaps a bearing job as well because it does pull heavy stuff mostly everyday.

Anyways still a beautifull sight!

Blowing The Whistle.

Much Much smoother than the first time, I'll be honest there.

Also there is still some tear down needed on the cluster shaft but that we will do once we rebuild it. For now the assessment can be made and the quotation there after.

I Got's Ya!

Another example of experience or learning from mistakes.

The previous tear down I hammered and the 1st gear jumped out of place and the sleeve along with it causing the dogs to jump out of place and when the next hammer blew came it must have knocked the gear and sleeve back in position but pinning the dogs between them.

They got squashed, the first time though and not this time! Nah this time I managed to pull them out before that!

Connecting the people of #HIVE across South Africa. #hive