TEA PROCESSING

Hi friends.

Its me again. Thank you for your support always. You are wonderful people.

Now good people, I visited a farm here in Kenya. It is a personal business, that means he has his tea farm where he harvests his tea from, transports his tea to his factory and processes it step by step before packaging the tea for sale. I will try to show you both on photo and some words the whole process. I am sorry in advance for any possible broken English and not being so articulate for I know its one thing to know or witness something and quite another to put it to your audience.

Tea is picked by hands here even though some companies have fully mechanized the tea picking and

Along the rivers are natural forests comprised of several species of plants which is impenetrable. Therein are snakes which range from pythons to the dangerous cobras, several species of birds and others small animals.

The businessman has grown hundreds of acres of forests. Trees from this forests are used as firewood for tea drying

After the tea is hand picked, it is collected and transported as fast as possible to the factory for processing. A couple of days ago I visited the factory to witness the processing. Visitors are not allowed mostly because of moving parts and the general danger involved in the processing.Drunkness is not allowed among the workers involved. Some workers have lost their limbs and some lost lives in the event of accidents. There is a lot of caution observed in this tea processing plant.

I counted there were 6 major steps involved as follows;

WITHERING where the raw tea leaves from the farm are exposed to the circulating dry air. This reduces the tea moisture content to 70 percent. Here there is both chemical and physical withering.I whether any which is added in the chemical withering but they told me that no chemical is added. The chemical withering is done in huge steel container where the withering is done faster whereas the physical is the old style where the tea is spear on a wire mesh beds.

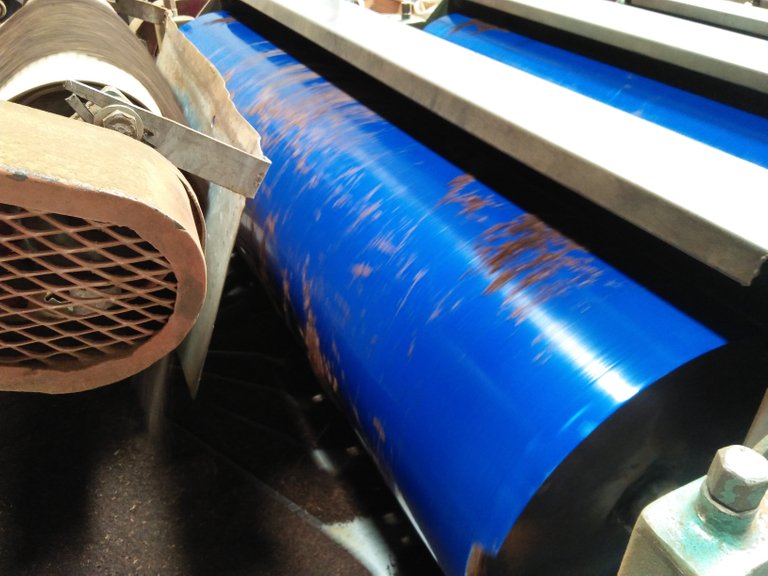

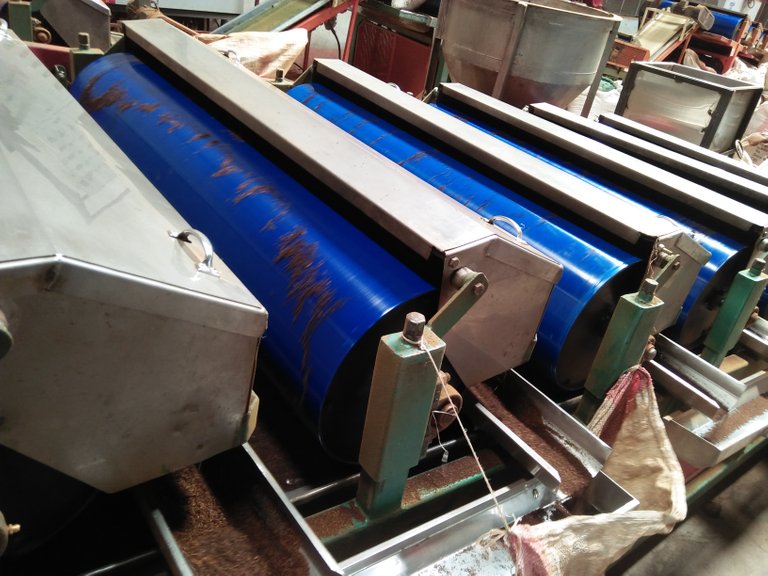

Then the withered tea is collected for the next process where CUTTING TEARING AND CURLING IS INVOLVED

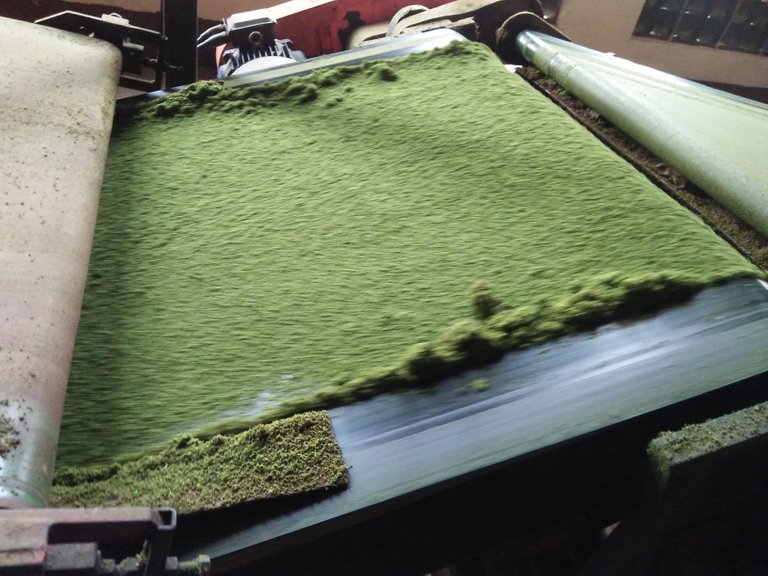

The third stage is FERMENTATION via the continuous processing unit(CFU)

Here the process of oxidation occurs. Oxygen combines catechins to form theoflavins(TF) and Theorubigins(TRS).

Theoflavins give the tea brightness and briskness while Theorubigins give the tea color and strength.

Remember the whole fermentation process is natural where natural air is circulated as the process naturally generates some heat.As you can see the color changes from green to brown in this fermentation process.

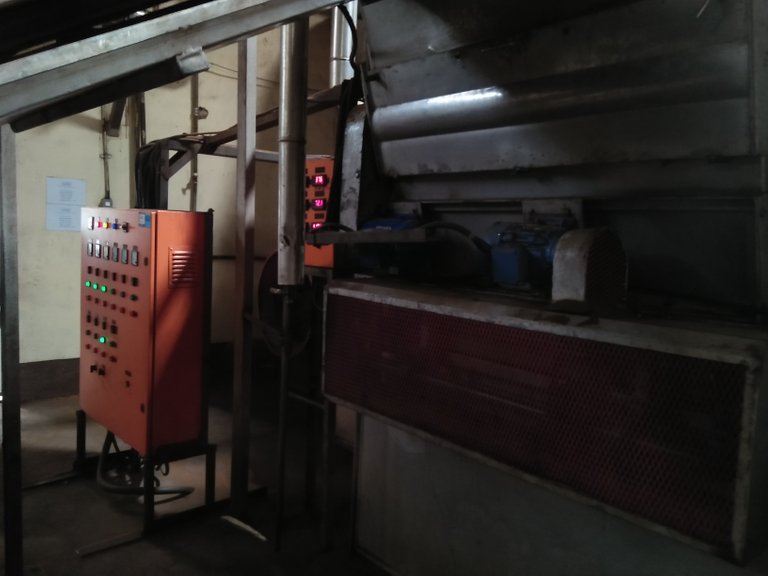

DRYING PROCESS is where the naturally fermented tea is exposed to hot compressed air. Firewood from the planted forests you saw above is used in the drying process. I felt like melting while passing through the driers. My guide told me that this is where most accidents occur to careless workers.

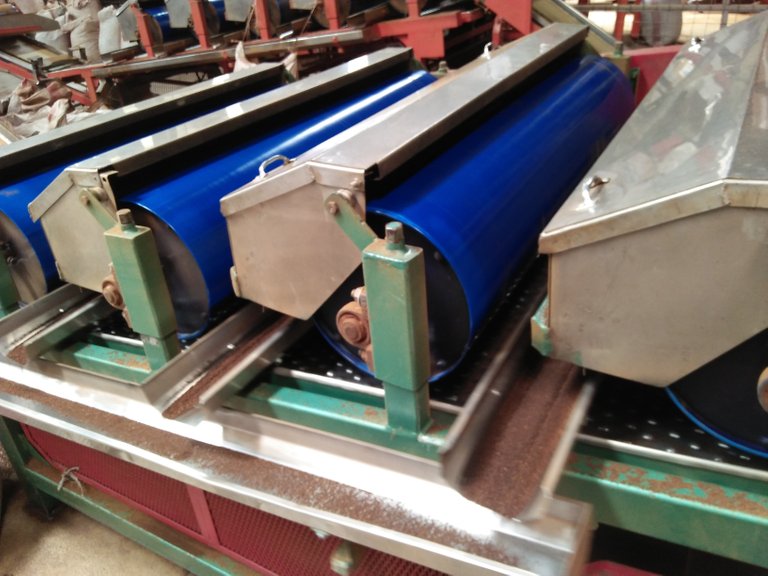

Then finally SORTING AND DISPATCH.In sorting the tea is grades as it passes through vibrating sieves

The the tea is tasted and the transported for auction and export.

https://youtu.be/8AYUOLHyo8ohttps://youtu.be/zW1-UOn8N40

They too have a large pack up power generator

The cutting, tearing and curling tools have lathes machines for sharpening them. A big maintenance section and well equipped.

Sorry for the long one. Thanks for going through. Be blessed always

Great look inside a tea factory! I didn't know it took souch heavy equipment to process tea....

Sharing!

💙💗🤠🧐👍🥳🙏