Water Treatment "Part 21": How does membrane filtration operate and what is it?

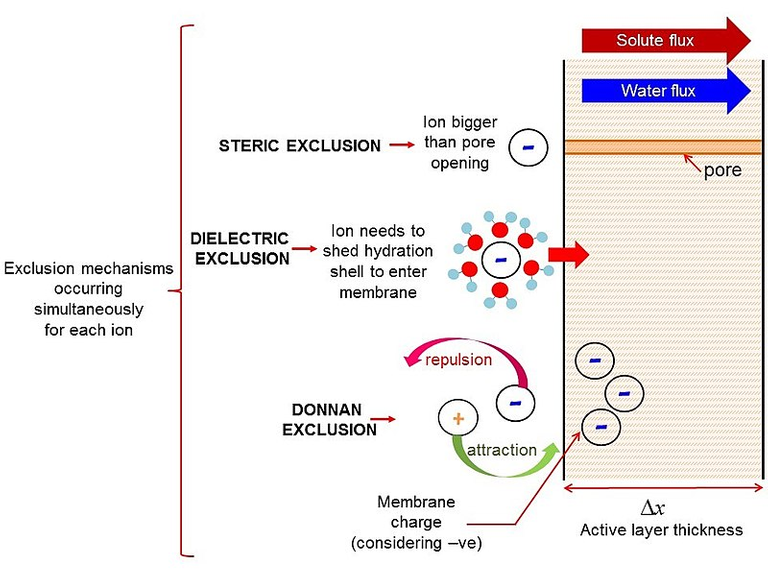

Membranes are made up of a very thin layer of materials that enable the separation of tiny substances dissolved in a liquid when influenced by driving forces. These forces may be the consequence of a difference in electrical potential, pressure, or concentration between the two sides of the membrane.

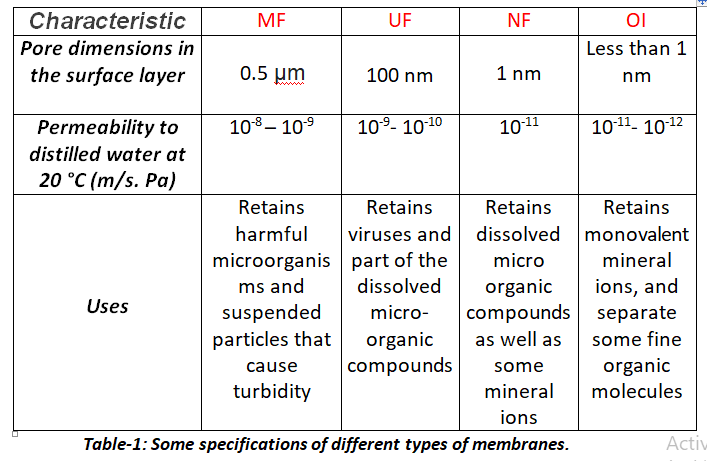

The four primary forms of membrane filtration that are used to categorise membranes are microfiltration (MF), nanofiltration (NF), ultrafiltration (UF), and reverse osmosis (RO). The requirements of the membrane must be known in order to select the proper procedure, regardless of the many categories that have been created. Moreover, the molecular mass of precipitates or colloids that a membrane can maintain is another factor used to categorise membranes.

Membranes' capacity to separate is influenced by both the sort of material they are constructed of and their porous structure. Table-1 shows some specifications of different types of membranes.

[Made using Microsoft Word]

Polyamides, polymers produced from cellulose, polysulfone, polyethersulfone, polyethylene, polyvinyl fluoride, and polycarbonate are the fundamental polymers utilised in the fabrication of membranes. Metals and metal oxides are also employed as inorganic materials.

With the exception of membranes used in microfiltration, which are made in the form of strips or tubes, membranes have an inconsistent structure. In other words, the outer layers of the membranes are very thin, ranging in thickness from 0.1 to 0.5 microns, and have fine porosity, while the inner layers are thicker and have much larger pores. The surface layer is where filtering occurs, while the bottom layers provide the membrane strong mechanical resistance. Surface and deeper layers may have different chemical compositions.

The permeability may be measured to assess the membrane's condition, including the occurrence of material deposition on its surface and pore blockage. The relationship between the permeability and the viscosity of the fluid that passes through the membrane is inversely proportional. If the temperature drops from 20 °C to 2 °C, for instance, the permeability falls by 40%.

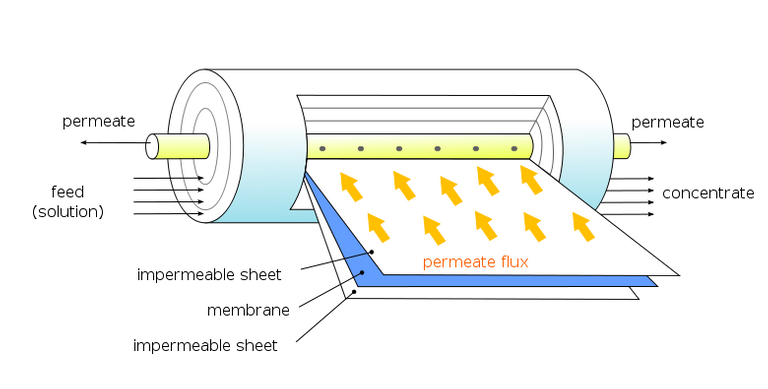

Spiral membrane modules:

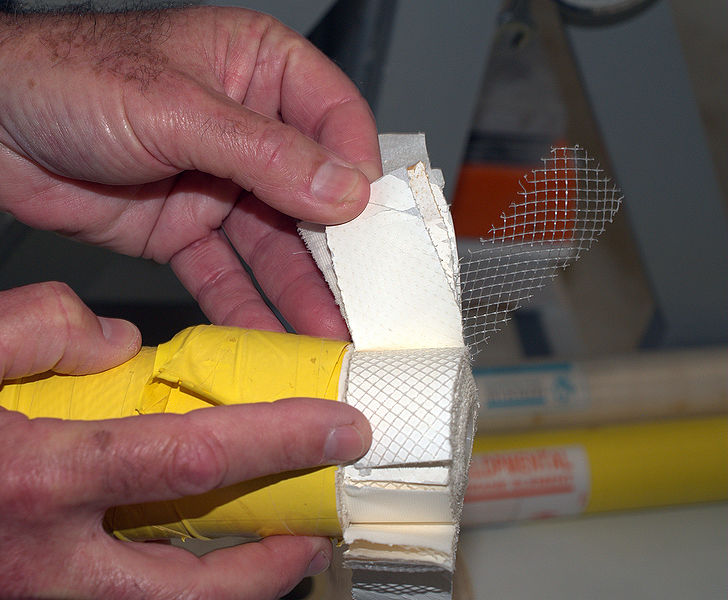

For this kind, membrane strips are tightly coiled around a tube with holes where the treated water is collected (Figure- 3). A plastic net keeps the membranes apart from one another, allowing the water to be treated to flow in an oblique direction. On the other hand, a softer plastic net keeps the membranes apart, allowing the treated water to be collected and sent to the collection pipe.

Figure-3: Spiral flow membrane module.

Tubular membrane modules:

The tubular shape has several tubes in it. The tubes are filled with the water to be treated, and the treated water is withdrawn from the outside of the tubes. The pipes include grooves that allow water to flow in an oblique direction; this is an excellent form for mechanical cleaning. Because of the size of the sloped channels, which disturbs the liquid's flow inside the pipes.

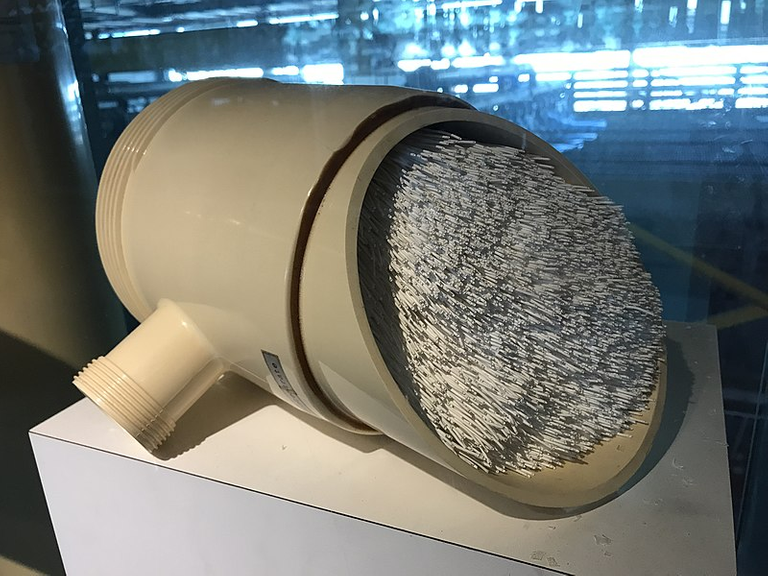

Hollow fibre membranes:

The interwoven threads are combined in parallel in two models. The first model is known as "Configuration internal-external," in which the treated water is brought in from the outside while the water flows through the interlaced threads. The second type is referred to as "Configuration external-internal"; in this system, water enters from the outside of the membranes and is treated within the membranes, with free flow throughout the filamentous network.

Figure-4: Cutaway of a microfiltration module with hollow fiber membranes at a NEWater plant

For the two versions, the membranes are bundled together and their ends are secured within the collecting channel's lid (Figure- 4), which separates the treated water from the untreated water.

- When necessary, a chemical treatment unit is included in the membrane treatment system used to produce drinking water together with a pre-treatment system, pumps, mixing equipment, and membranes.

References:

- [Introduction to Water Chemistry (Pollution- Treatment- Analysis). Dr. Nasser Al-Hayek. Publication of the Higher Institute for Applied Sciences and Technology (HIAST). Syrian Arab Republic, 2017.]

- Taparhudee, Wara (2002). "Applications of Paddle Wheel Aerators and Diffused-Air System in Closed Cycle Shrimp Farm System" (PDF). Witthayasan Kasetsart (Sakha Witthayasat). 36: 408–419. Retrieved 26 April 2020.

- Unsafe water kills more people than war, Ban says on World Day". UN News. 22 March 2010. Retrieved 10 May 2018

- Raymond Desjardins- Livre: Le traitement des eaux- 2éme edition- Ecole Polytechnique de Montréal- 1997- ISBN 2-553-00643-8

- Drinking Water Treatment- EDX- Delft University of Technology.

- Book- Drinking Water: Principles and Practices- by Hans J C Van Dijk (Author), Jasper Q J C Verberk (Author), Peter J De Moel.

Thanks for your contribution to the STEMsocial community. Feel free to join us on discord to get to know the rest of us!

Please consider delegating to the @stemsocial account (85% of the curation rewards are returned).

You may also include @stemsocial as a beneficiary of the rewards of this post to get a stronger support.