A Hands-On Welding Experience: Empowering Learners with Skills for the Future

One of the self Reliance courses we offer at church is the Education for better work. We believe that the glory of God is intelligence so as long as we are capable to learn we should never stop learning and acquiring new skills.

At our welding training workshop, we witnessed something truly remarkable: first-time learners diving into the art and science of welding with enthusiasm and excitement. For many of them, it was their first hands-on experience with this essential trade, and their energy was palpable. Thanks to our skilled and passionate facilitator, my husband, they not only learned the theory behind welding but also got the opportunity to put that knowledge into action. Here’s a glimpse into their journey and how the right training and hands-on experience can make all the difference.

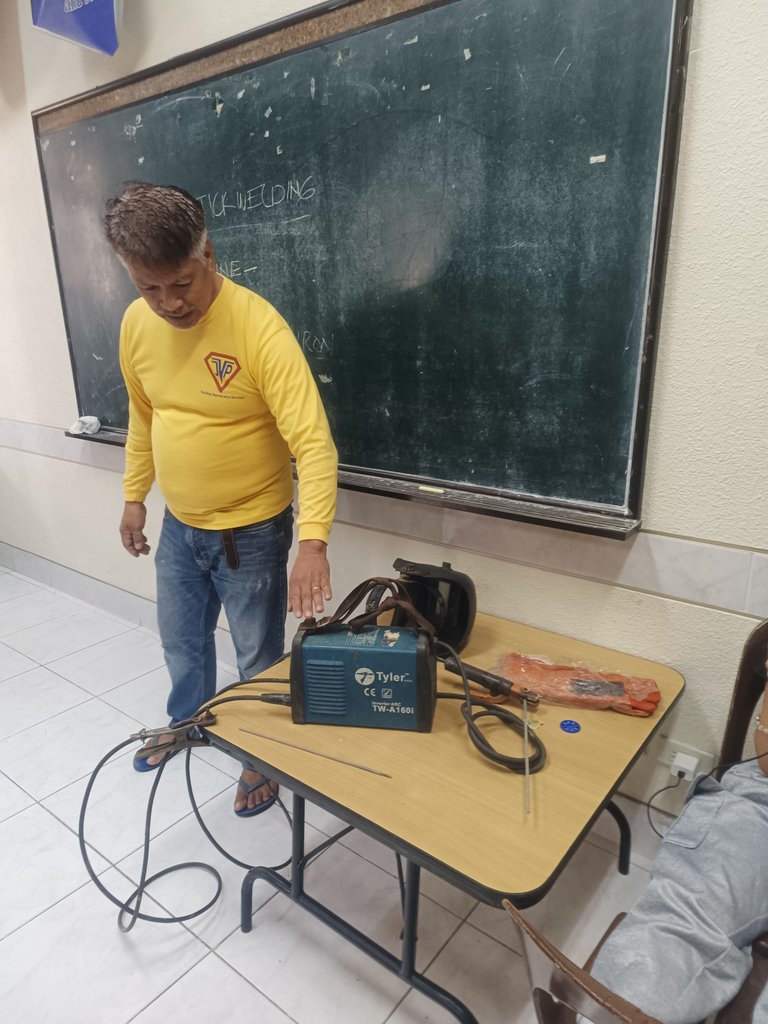

Setting the Stage with Theory before anyone picked up a welding torch, we knew it was crucial for our students to understand the basics. Our facilitator, my husband, began by introducing the different types of welding methods: TIG (Tungsten Inert Gas), MIG (Metal Inert Gas), and SMAW (Shielded Metal Arc Welding). Each type has its own specific uses, benefits, and techniques, and it was important that our students grasp the theory behind these processes before proceeding with any actual welding.

By breaking down these welding techniques, our students could better understand when and why each method is used. For example, TIG welding is known for its precision and is ideal for welding thin materials like stainless steel, whereas MIG welding is faster and perfect for larger projects. SMAW, often referred to as stick welding, is one of the oldest and most versatile techniques, suitable for outdoor work and thicker materials. My husband’s clear, step-by-step explanations made sure everyone understood the basics before they touched the equipment.

Understanding the Tools of the Trade

Once the theory was laid out, it was time for the participants to learn about the different kinds of sticks or electrodes used in welding. This might seem like a small detail, but it’s critical for ensuring the right weld on the right material. Each type of welding electrode has its own unique characteristics, and knowing when to use them makes a huge difference in the final result.Our facilitator explained how the choice of electrode varies depending on the type of material being welded and the kind of welding process being used. Whether it’s a mild steel electrode for SMAW or a more specialized tungsten electrode for TIG welding, knowing which electrode is right for the job can make or break the outcome.

The Magic of Hands-On Learning

After the theory and tool discussion, it was finally time for the participants to step up to the welding stations. For many, this was a moment they had been eagerly anticipating—the chance to weld for the first time. There’s something incredibly satisfying about holding the welding torch in your hands, feeling the heat and intensity of the arc, and seeing the metal come together in a seamless bond.

The learners were initially a little nervous, but once they saw the sparks fly and experienced the power of the welding process, they quickly gained confidence. My husband was right there with them, guiding their hands, correcting their stances, and offering tips on everything from controlling the heat to maintaining a steady hand. It was evident that his experience and patience made a significant difference. He’s not just a skilled welder; he’s a dedicated trainer who genuinely cares about the success of his students.

Seeing the Results by the end of the class, each participant had completed their first welds and left with a sense of accomplishment. They were amazed at how much they learned in just one session, and many expressed how much they enjoyed the hands-on experience. Some were surprised at how easily they could make a weld after just a few hours of practice, while others were excited to continue developing their skills further.

The beauty of welding is that it’s not just about theory—it's about action. There's no substitute for getting in there, making mistakes, learning from them, and improving with every weld. That’s what makes the process so rewarding. Our participants not only gained valuable technical skills but also a newfound appreciation for the craftsmanship involved in welding.

The Road Ahead

We’re proud of the progress our students made in this introductory class, and we’re excited to continue offering these hands-on training sessions. Welding is a skill that opens up countless doors for employment and personal projects. Whether you want to work in construction, manufacturing, or even pursue artistic endeavors, welding is a versatile skill that can lead to many opportunities.

My husband’s dedication to teaching welding, combined with our hands-on approach, ensures that each participant receives personalized attention and guidance. We look forward to seeing our students grow and thrive in this trade.

After of course the seemingly nervous experience with making your own fire works using the sticks, Hahaha. We had a simple luncheon together. I cooked chicken Adobo for lunch. Everyone enjoyed the sumptuous meal.

Then we left and brought everyone back to our church for we still have many activities in the afternoon.

Everyone had a great time, specially the shouts you hear from them everytime the stick creates sparks. While cooking I can hear all of them laughing their hearts out with excitement while holding the torches.

Thanks for reading this far.

How about you, have you had an experience learning a new skill?

How was the feeling?😍☺️

Please do share and tell.

Wow...bless you both, specially to Joseph sharing his skills and knowledge to young generation.

Thank you mother dearest.

⋆ ᴛʜᴇ ᴘʟᴀᴄᴇ ғᴏʀ sᴏᴜᴛʜᴇᴀsᴛ ᴀsɪᴀɴ ᴄᴏɴᴛᴇɴᴛ ᴏɴ ʜɪᴠᴇ

⋆ sᴜʙsᴄʀɪʙᴇ ᴛᴏ ᴛʜᴇ ᴀsᴇᴀɴ ʜɪᴠᴇ ᴄᴏᴍᴍᴜɴɪᴛʏ

⋆ ғᴏʟʟᴏᴡ ᴛʜᴇ ᴀsᴇᴀɴ ʜɪᴠᴇ ᴄᴏᴍᴍᴜɴɪᴛʏ ᴠᴏᴛɪɴɢ ᴛʀᴀɪʟ

⋆ ᴅᴇʟᴇɢᴀᴛɪᴏɴ ʟɪɴᴋs 25 ʜᴘ⇾50 ʜᴘ⇾100 ʜᴘ⇾500 ʜᴘ⇾1,000 ʜᴘ

Thank you so much @asean.hive